Over 75% of the world’s steel is made with our Argon Oxygen Decarburization (AOD) process. Lower your material costs, produce cleaner metals and increase productivity with AOD.

Over 75% of the world’s steel is made with our Argon Oxygen Decarburization (AOD) process. Lower your material costs, produce cleaner metals and increase productivity with AOD.

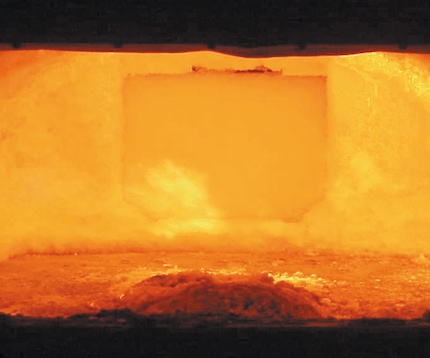

Used in foundries, mini-mills and stainless steel mills, our COJET® gas injection and supersonic direct injection processes lower costs and improve furnace productivity.

Our dilute oxygen-enhanced combustion system helps convert your furnace air-fuel burners into oxy-fuel burners. This may increase your productivity and help decrease fuel consumption.

REBOX® flameless oxyfuel combustion technology is used in steel reheating for increased capacity, fuel savings, improved temperature homogeneity, and reduced NOx emissions.

Our stove oxygen enrichment application can help you reduce or potentially eliminate the need for fuels like coke oven gas and natural gas while generating higher blast temperatures.

Our hot oxygen system rapidly burns hard to combust materials and easily preheats oxygen to high temperatures at point of use, to give you the best possible results.

OXYGON® ladle preheating technology moves beyond conventional burner designs to harness highly efficient flameless oxyfuel combustion for significant energy savings.

Products, systems and services for metals

Gases and other applications for metals