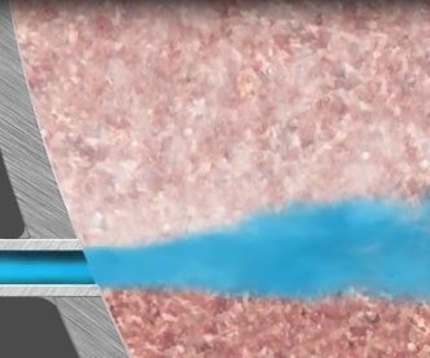

CRYOLINE® brand in-line tunnel and spiral freezing systems use cryogenic gas impingement to remove heat rapidly and uniformly from beef and pork products.

Beef up your productivity. Whether you are dealing with raw or cooked product, Linde has a system that can help improve your productivity and throughput, without sacrificing product quality.

CRYOLINE® brand in-line tunnel and spiral freezing systems use cryogenic gas impingement to remove heat rapidly and uniformly from beef and pork products.

Product that is chilled to firm improves handling, minimizes moisture loss and slows bacterial growth. Controlling product temperature maintains yield and product value.

Heat generated during mixing and grinding can accelerate bacterial growth and lead to off-flavors, decreased shelf life and spoilage. Here are ways to protect your product.

We exhibit new offerings and present in-depth discussions at market conferences and industry trade shows throughout the year.

March 15, 2026 - March 18, 2026

At the IIAR National Refrigeration Conference & Expo, Linde will display and discuss the NITROBOOST® supplemental refrigeration system. The Linde system adds to or returns lost cooling capacity to existing mechanical freezers.

March 15, 2026 - March 17, 2026

Seafood Processing North America is North America’s largest seafood exposition. Exhibiting suppliers offer the newest seafood products, processing and packaging equipment, and services available for the seafood market.

March 18, 2026 - March 20, 2026

The Advanced Bioeconomy Leadership Conference (ABLC) addresses the most important issues in the Circular Bioeconomy right now. Linde will discuss their well-known air separation technologies, as well as new developments in low carbon hydrogen and electrolysis technologies.