Gases, Technology & Equipment to Optimize Your Process

Manufacturing & Materials Processing

Helping You Obtain the Best Results for Today's Demands

Made to LastAt Linde, we will work with you to help you obtain the best results for today’s demands. We offer years of experience in the field, a diverse portfolio of heat treating, process, and specialty gases, and applications technologies that can improve the quality and appearance of your products, help you make highly reproducible parts, and give you more control over your process.

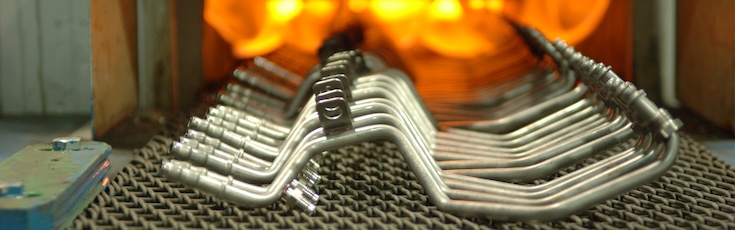

Heat Treating

Our gas portfolio includes a wide range of heat treating, process, and specialty gases to enhance product quality and appearance, and improve part reproducibility.

Improve your heat treating operations

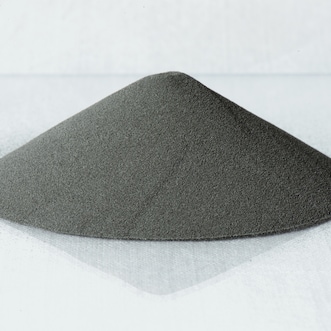

Additive Manufacturing

Process gases play a vital role in additive manufacturing and are involved in every step of the fabrication chain – from metal powder production through 3D printing.

Explore gases for powder producers

Hot Isostatic Pressing (HIP)

Proper atmosphere control is key in hot isostatic pressing. The simultaneous application of high temperature and pressure, plus Linde's argon or nitrogen gas, helps improve the metal's mechanical properties.

Learn more about gases for HIP

Related Products

Products to enhance your materials processing and additive manufacturing.

Find the right product to enhance your process

Linde offers various capacity requirements of gases, from cylinders to on-site systems for manufacturing & materials processing. We can provide you with what you need for your specific application from fuel enrichment and metal treatment to atmospheric control.

Related Gases

Need more information?

Call us at 1.844.44LINDE (1.844.445.4633) or send a message using the link below.

Ask a question, Request a quote