Gases and Technologies for Your Heat Treating Applications

Enhance Your Carburizing and Hardening Processes

Consistent Process Control

Carburizing is a hardening process in which carbon diffuses into the surface layer of a steel part at a temperature high enough to change the steel grain structure. This change enables the steel to absorb carbon. The result is a wear-resistant layer that makes carburizing an ideal process in producing strong, safe metals.

Control of the carburizing process is measured to industry specifications, enabling consistent process control batch after batch. In certain cases, alterations to the atmosphere can be made that may accelerate the carburizing speed and increase efficiency. A suspended carburizing process also eliminates the need for emptying pusher furnaces for weekend shutdowns — resulting in minimum delays and increased productivity.

Vacuum Carburizing

Vacuum carburizing—also known as low pressure carburizing (LPC)—demands an atmosphere that is highly reproducible and highly controllable. The right carbon source for this process has been available for use since well before the vacuum heat treating process was developed. Linde’s nitrogen and methanol technology, combined with a precise atmosphere control system can provide ideal conditions for better control and repeatability.

Case Hardening

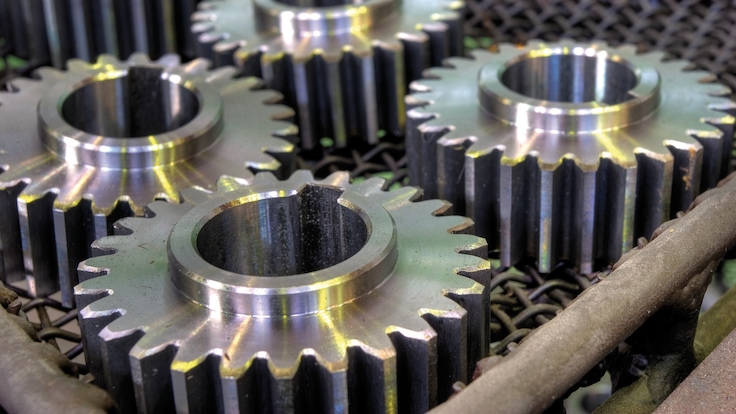

Ferrous metals are normally hardened by heating to a required temperature. The metal is then cooled rapidly in a quenching medium, such as oil, water, or brine, increasing the hardness and strength of the metal. Neutral hardening and tempering produce toughness on parts that will be highly stressed. Case hardening is an ideal heat treatment for parts that require a wear-resistant surface and a tough core, such as gears.