Ask a Question. Get a Quote.

Get answers for your process.

Contact us

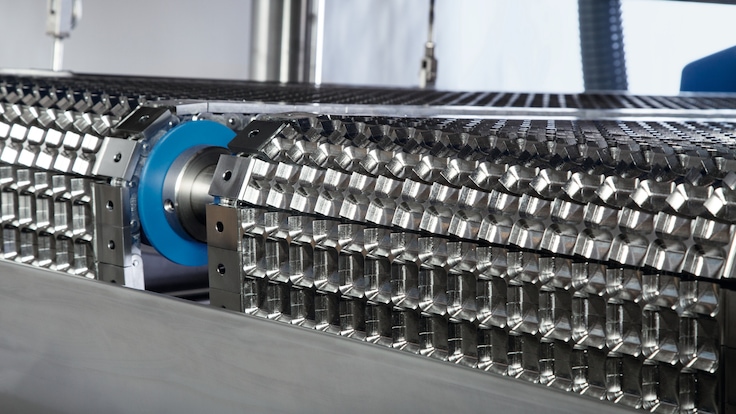

This patented freezer will produce IQF pellets in a regular size with high repeatability, opening up many possibilities for the modern food processor. The CRYOLINE® PE pellet freezer works by simply filling the cavities in a belt pre-cooled by liquid nitrogen. The extremely low temperature of the belt rapidly freezes the liquid into the shape of the cavity before it is released at the end of the belt. PE Market Information Sheet

The controlled residence time needed in a space-saving design to finish freezing your inclusion product and maintain its superior quality. Some processing examples of incorporating frozen pellets made from your liquid food formulations might be:

|

• Pasta Sauces |

• Gravies & Glazes |

|

• Cheese Sauces |

• Purées |

|

• Convenience Meals |

• Concentrates |

Either savory or sweet, functional or flavorful - capturing your product in pellet form to use as a mix-in ingredient, flavor boost or health attribute will help create the exact end product that satisfies your customer's request. Creating frozen pellets from liquid foods and health-based compounds achieves uniform distribution and improved handling for products like:

| • Probiotic formulations | • Dairy-based foods |

|

| • Nutritive supplements | • Novelty frozen foods | |

| • Flavor concentrates | ||

See what else Linde provides for the food industry. Return to the Home Page