Ask a Question. Get a Quote.

Get answers for your process.

Contact us

The versatile CRYOLINE® CVT cryovantage tunnel freezer is engineered to meet lower capital outlay. These workhorse freezers are capable of freezing and chilling a wide variety of products and are an integral part of your continuous processing operation. This straight tunnel freezer incorporates many proven technologies that ensure quick, thorough freezing and maintains the quality attributes of your products. This basic cryogenic tunnel freezer incorporates many sanitation improvements that make it faster and easier to clean and meets the USDA sanitation standards. Read more about this tunnel freezer.

In line with your production flow, your product moves through the tunnel freezer on a continuous conveyor belt. Cryogen injected into the freezer contacts the individual food product pieces for optimum heat transfer. Automatic temperature control systems adjust cryogen injection to compensate for incoming product load and temperature variations. The internal fan system increases production capacity and helps insure evenly chilled products. Adjustable curtains at the conveyor entrance and exit prevents warm room air from entering freezer. These standard features help conserve cryogen and optimize freezer performance. CVT Market Information sheet

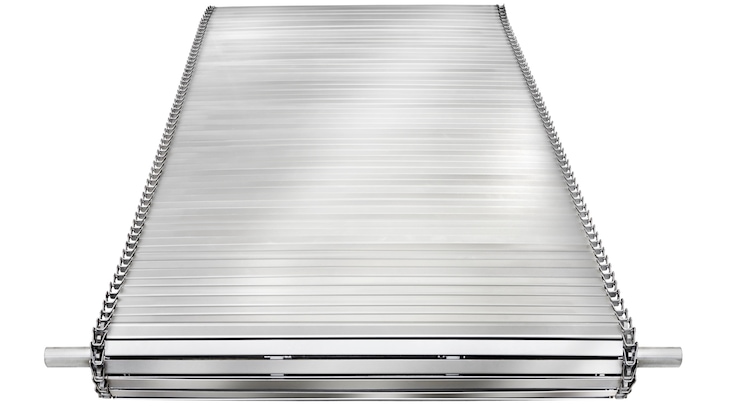

The CRYOLINE® PB plate belt freezer improves product yield for food manufacturers by minimizing product loss during freezing. The plate belt tunnel freezer features a specially designed solid stainless-steel segmented conveyor belt to crust freeze difficult to handle products, such as raw, marinated proteins, sauced foods, and semi-liquid products. A frozen crust is quickly formed on products in the liquid nitrogen-powered freezer, making them easy-to-handle and increasing yield by reducing moisture loss. Additional information about the plate belt surface.

Using a solid surface conveyor belt in lieu of a chain link belt reduces belt marks and practically eliminates sticking and dripping, which improves sanitation and cleanability. The belt is chilled in the freezer to cryogenic temperatures. So as products are placed on the solid belt, the outside surface quickly freezes through contact with the cold plate belt. Crust freezing locks-in moisture, brine, marinade, and sauces, so there are minimal losses in downstream processing steps. PB Market Information Sheet

Lock in moisture, preserve flavor and ensure proper texture with the right system for individually quick frozen (IQF) products. Ideal for small products or those that are wet, sticky or difficult to handle such as diced meats, produce and seafood, our CRYOLINE® UPF ultra performance flighted freezer provides maximum cryogen exposure — gently tumbling your products to produce excellent quality in IQF products. Our flighted freezer system helps processors maximize yield and increase production capacity while maintaining a high level of quality while lowering freezing costs.

In order to produce the highest quality IQF product, the Linde system exposes the product to cryogen at the freezer entrance ensuring a quick crust freezing. Short individual belt flights gently tumble foods for reduced fines and deliver even, quick freezing on all surfaces. Yield is also maximized through direct cryogen injection at key points throughout the freezer tunnel. Additionally, a wider belt width results in shorter tunnel lengths, allowing processors to maximize throughput while conserving valuable floor space. More on the benefits of IQF production.

Our latest flighted freezer design has a track record of success at customer installations throughout the United States using either liquid carbon dioxide (CO2) or liquid nitrogen (N2). Either raw or cooked foods can be frozen into excellent quality IQF products using this system. UPF Market Information Sheet

The success of the CRYOLINE® UPT ultra performance tunnel comes from the way the experts at Linde have perfected the delivery of both the cryogenic liquid and vapor circulation. This new approach gets much more cooling power from the same amount of cryogen used in existing systems. The ultra performance tunnel has improved distribution control of the liquid cryogen that directly contacts the product. The difference is that the cold vapor circulation is extracting additional cooling potential that would otherwise be underutilized. Add to that the new vapor lock systems at both the conveyor entrance and exit to control cryogenic vapor and minimize air and moisture infiltration into the system. Improving cryogen conservation, boosting productivity and increasing yield improves your profitability. Additional details about this high-performance tunnel.

The CRYOLINE® UPT ultra performance tunnel freezer takes the power of cryogenics to a whole new level. The freezing system was created to address customer needs to increase product throughput and boost productivity in the same or smaller footprint of existing cryogenic operations. Contact us for more information about the possibilities. The ultra performance freezer, as with all cryogenic systems from Linde, is easily integrated into existing production line configurations. UPT Market Information Sheet

Your floor space is one of your most valuable assets and you need to make equipment purchase decisions with careful consideration to size and performance. Linde can give you the best of both worlds. Our CRYOLINE® UPS ultra performance PLUS spiral freezer delivers more cold per square foot in a compact footprint to minimize its impact on the manufacturing floor. And the spiral design offers advanced cryogenic delivery ideal for any freezing and chilling application. Further details are found here.

Improved cryogen impingement and vapor flow make optimum use of cryogen and significantly reduce the time necessary for heat transfer—resulting in a more rapid chill for a better-quality product, increased yield and improved production efficiencies. The spiral freezer’s patented vapor balance system minimizes air and moisture infiltration into the system, while also conserving cryogen. The reverse-flow center fan design recirculates the cryogen vapor to help optimize freezer performance. The efficiency of the ultra-performance PLUS spiral freezer can be enhanced with product pre-chilling. UPS PLUS Market Information Sheet

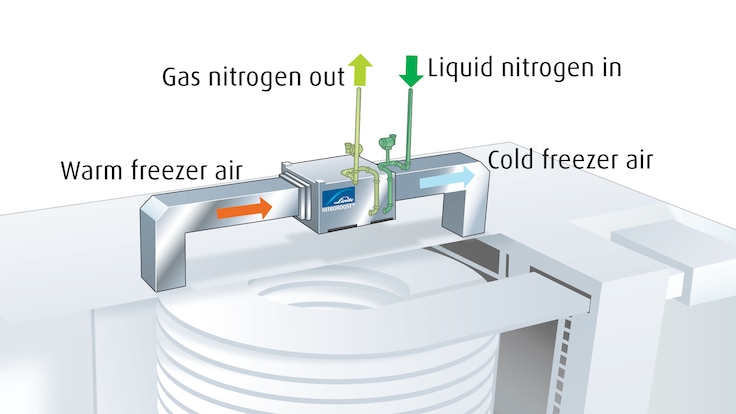

The new liquid nitrogen powered NITROBOOST™ supplemental refrigeration systems give manufacturers the ability to maintain target operating temperatures in their existing mechanical tunnel and spiral freezers (NITROBOOST™ ST) or blast-style freezers (NITROBOOST™ BL). This avoids production downtime and the related temperature issues that occur from high heat loads and exceeding the freezer’s capacity.

Boosting Mechanical Freezers

Added to a blast or shock freezer, the NITROBOOST™ BL system from Linde helps under-performing or overloaded freezers reach the desired operating temperature faster. Processors can now keep products within specific temperature ranges and avoid the need to reduce freezer loading or operate additional hours or shifts. Much more about the NITROBOOST technology

Mechanical Spirals and Tunnels Also Benefit

The NITROBOOST ST system detects when the mechanical freezer is trying to reach its target operating temperature and triggers the liquid nitrogen flow to accelerate the cool down process to maintain a consistent operating temperature. The NITROBOOST ST system coils also can be set to defrost at different times relative to the mechanical system to optimize freezer production, defrosting and sanitation schedules.

NITROBOOST™ ST supplemental refrigeration for spiral and tunnel freezers

NITROBOOST™ BL supplemental refrigeration for blast freezers

The cabinet freezer can be used with either liquid nitrogen or carbon dioxide, giving a greater flexibility in applications. The freezer comes in a single or twin model size. The twin orientation has fans on both sides of the cabinet. The twin unit gives a faster and more even freezing for more demanding products. The standard single unit has fans on just one side of the cabinet and is used for smaller product runs. Optimized batch freezing details.

Other options available include doors front and back for push-through work where the freezer may be placed between raw and cooked/cooled areas. For larger capacities, it is also possible to have two cabinets joined together with a cold gas transfer between them, enabling optimal refrigerant application. Contact Us to speak with a regional engineer about a system that's optimal for your production needs.

In line with modern standards, the freezer has been designed with hygiene requirements as a top priority. The cabinet is made from all stainless-steel components and is fully welded inside. The interior of the cabinet freezer is optimized for cleaning. There are only a few internal parts and all are removable for a thorough wash down. CF Market Information Sheet

Moisture and flavor retention help increase product yield and maintain a high level of freshness, taste and quality. Our engineers designed an immersion freezing system that utilizes either a conveyer belt or top-loading option, depending on the type of product being frozen. In addition, our system offers the maximum achievable bath length without wasting floor space. We don’t waste nitrogen either, as we’ve designed it to use the minimum amount of nitrogen necessary for both cool down and freezing.

The Upper (and Lower) Crust

The immersion system offers the most rapid type of freezing method in the industry, resulting in an instant crust freeze. This importance of the crust freeze is readily apparent for products such as marinated chicken tenders, flavored seafood patties or filets, smaller diced product like vegetables or berries and more delicate seafood including scallops and clams. Crust freezing prior to final deep-freezing reduces product dehydration, locks in flavor and helps maintain product shape, for a more attractive end result. In addition, the crust freeze ensures smoother and more rapid processing because the crust freeze prevents product from sticking to the conveyor belt. This step may also be used to pre-chill product prior to a more thorough freeze in a spiral or tunnel freezer. Contact Us for more insight about immersion freezing with Linde cryogenic liquid nitrogen. UPI Market Information Sheet

To produce frozen pellets of sauces, purees and other liquid foodstuffs, processors use the CRYOLINE® PE 800 freezer from Linde. This patented freezer will produce IQF pellets in a regular size with high repeatability, opening up many possibilities for new food product offerings. The pellets are easily added to frozen, prepared meals. Additional information about the Linde pellet freezer.

The CRYOLINE® PE works by simply filling the cavities of a liquid nitrogen, pre-cooled belt. The extremely low temperature of the belt rapidly freezes the liquid into the shape of the cavity, thereby stabilizing the product before it is released at the end of the belt. If you are producing for the catering or retail market, the frozen pellets will allow your customer to defrost as much or as little of the product pellets as required, giving you the edge over your competitors. PE 800 Market Information Sheet

Linde's ongoing support of the systems we install includes keeping an inventory of OEM parts suitable for our temperature control systems. Our program makes it easy to request parts and receive them in a timely manner to keep your production up and running. Read about our parts service and make an on-line request

Check out the processing options for your specific product market

Linde continually expands product and service offerings guided by our key market competencies. Here are our latest applications