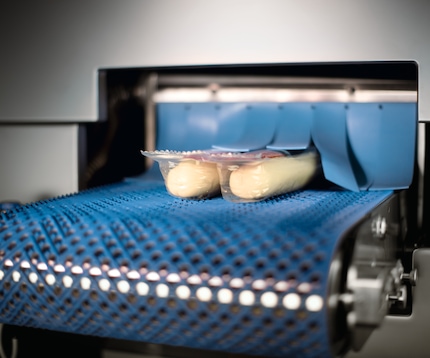

CRYOLINE® in-line freezing and ACCU-CHILL® chilling systems for bakery production results in productivity gains and offers process line flexibility options. Freezing raw products to lock in freshness or finished products to extend shelf life and expand market reach are the Linde benefits.